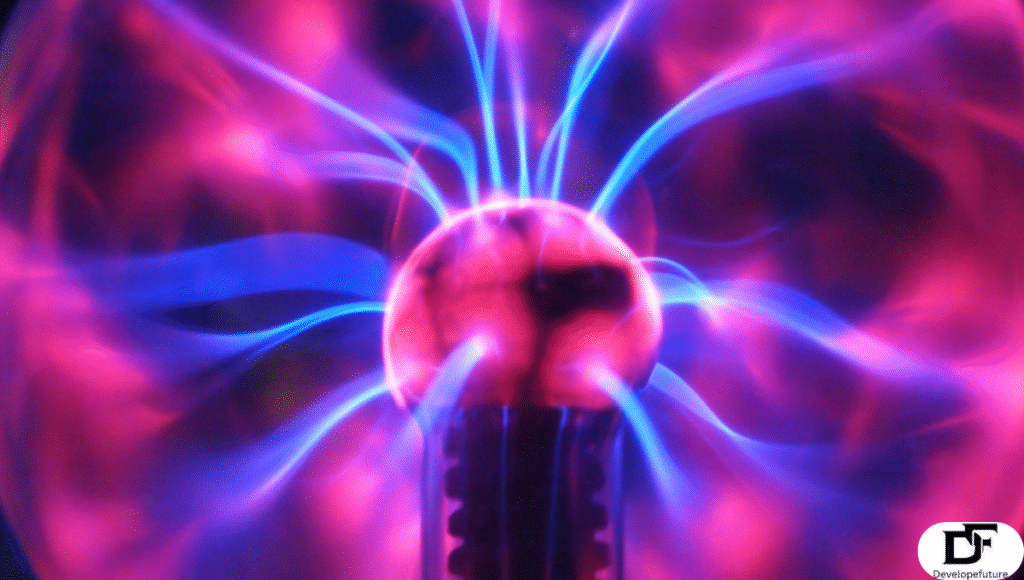

Plasma is often described as the fourth state of matter. It’s distinct from solids, liquids, and gases, unlike the familiar forms of matter. It is composed of charged particles—ions and electrons. They move freely and interact dynamically with electric and magnetic fields. This unique combination of high-energy particles gives plasma properties. These are useful in a wide range of scientific and industrial applications.

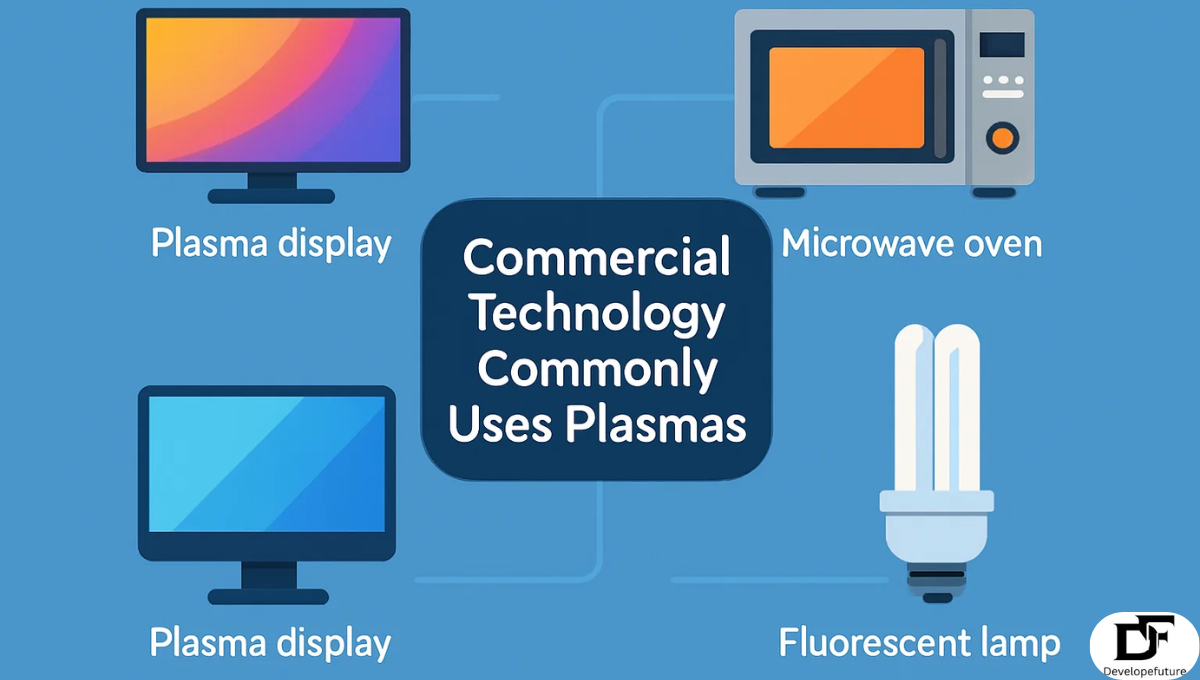

In everyday life, many people associate plasma with natural phenomena. Such as lightning, the aurora borealis, or even the glowing stars in the night sky. But plasma is not confined to natural events. It is deliberately generated and harnessed in various commercial technologies. Some of these applications are so integrated into daily living. That people may not even realize plasma plays a key role in their functionality.

Which commercial technology commonly uses plasmas can be answered by looking at industries. Where plasma is indispensable. Plasma is essential in flat-panel displays. Its use in semiconductor manufacturing, medical sterilization, and surface modification. It is for environmental protection systems and advanced lighting. Among these, plasma display panels, semiconductor etching, and plasma-based sterilization technologies are some of the most recognized and widely adopted.

Here we explore the role of plasma in commercial technology. We are examining how it works, the benefits it provides, and its impact across industries. By the end, it becomes clear. That plasma is not an obscure scientific curiosity. But a practical and transformative tool shaping modern technology.

Table of Contents

Display Panels

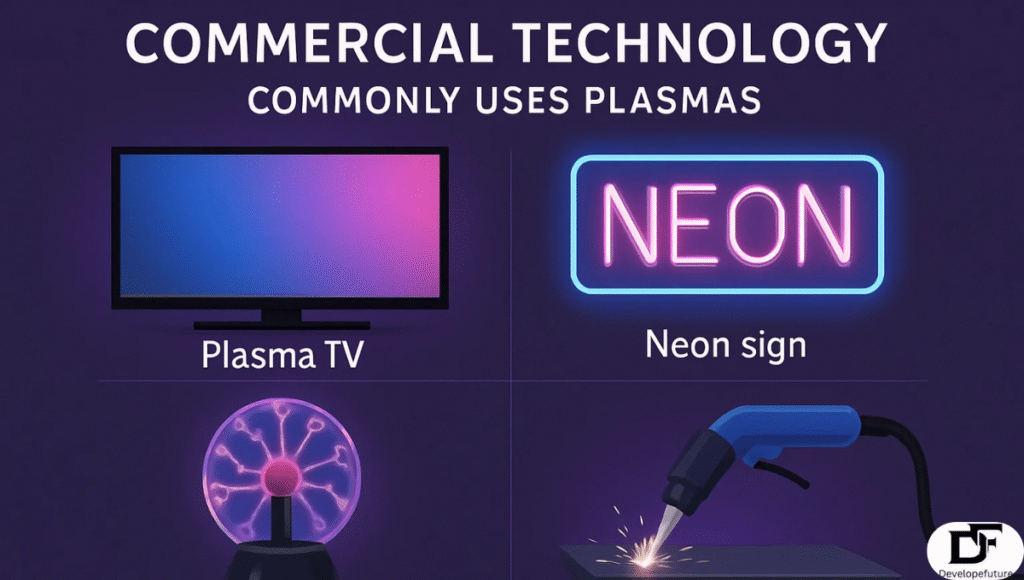

One of the most well-known commercial uses of plasma technology has been the plasma display panel (PDP). For decades, plasma TVs were a staple of home entertainment systems. It is prized for their vivid colors, wide viewing angles, and high contrast ratios. The working principle of these displays was rooted in plasma physics. Where tiny cells filled with inert gases. Such as neon and xenon were electrically charged to create light.

When an electric current passed through the gas-filled cells. It ionized the gas and formed plasma. This plasma emitted ultraviolet light. Which in turn excited phosphor materials coated inside the cell walls. As the phosphors fluoresced, they produced visible light in red, green, or blue. Which combined to form the full-color image seen on the screen. This process allowed plasma screens to produce images with exceptional brightness. And accuracy compared to earlier display technologies.

While displays have largely been replaced by LED and OLED technology. It’s due to their greater efficiency and thinner form factors. PDPs remain a landmark example of how plasma entered mainstream consumer markets. The commercial success of plasma televisions is demonstrated. That plasma could be harnessed for large-scale, reliable, and visually stunning technologies.

In Semiconductor Manufacturing

The most significant and enduring commercial application of this technology lies in semiconductor manufacturing. The chips that power smartphones, computers, medical devices, and countless other electronics could not exist without its processes. Its etching and plasma-enhanced. Deposition techniques are critical for fabricating the nanoscale structures inside modern integrated circuits.

Plasma etching uses reactive ions to selectively remove material from a semiconductor wafer with high precision. Unlike traditional chemical etching. Plasma etching allows engineers to achieve extremely fine patterns required for today’s microchips. Plasma enhanced chemical vapor deposition (PECVD). So, we use it to deposit thin films of material at relatively low temperatures. It enables the layering of complex structures.

These plasma-based processes provide high accuracy, uniformity, and control. These are indispensable in creating billions of transistors within a single chip. As semiconductor devices continue to shrink in size. As it increases in complexity, its role becomes even more critical. Without plasma, the modern electronics industry simply could not function.

Plasma Sterilization

Another commercial technology that commonly uses it is medical sterilization. Hospitals and pharmaceutical companies rely on it-based sterilization systems. It ensures that surgical instruments, implants, and medical devices are free from harmful pathogens, unlike traditional methods such as steam sterilization or chemical disinfectants. Its sterilization offers unique advantages.

Low-temperature sterilization works by creating it. From hydrogen peroxide or other gases inside a sterilization chamber. It generates reactive species—such as free radicals and UV photons. That they effectively destroy bacteria, viruses, and spores. Because this process occurs at relatively low temperatures. It can sterilize delicate instruments. And devices that would be damaged by heat or moisture.

Its sterilization is fast, effective, and environmentally friendly. It leaves behind only water vapor and oxygen as byproducts. This makes it increasingly popular in commercial medical facilities. By reducing the risk of infection and ensuring patient safety, its sterilization has become a critical component of modern healthcare infrastructure.

Surface Modification with this Technology

It’s also widely used in commercial industries for modifying the surfaces of materials. This includes cleaning, etching, coating, and improving adhesion. For example, its treatment applied to plastics, glass, textiles. And metals to alter surface properties without changing the bulk material.

In the packaging and automotive industries, its treatment helps increase the wettability and adhesion of surfaces. It allows inks, adhesives, and coatings to bond more effectively. When producing food packaging, plastics are often treated with it to ensure that printing inks adhere properly. In the automotive industry, its cleaning ensures strong bonding between coatings and metallic surfaces.

The ability to change surfaces without harmful solvents or chemicals. Makes it a sustainable and commercially attractive technology. Its applications range from consumer goods to aerospace components, highlighting its versatility.

Plasma in Lighting Technologies

Before the widespread adoption of LED lighting, it was central to many commercial lighting systems. Fluorescent lamps and neon lights, both of which rely on its discharge. It has illuminated homes, streets, and businesses for decades. Even today, neon signage remains an iconic and widely used commercial technology.

In these systems, an electric current passes through a gas-filled tube, creating it. It emits ultraviolet radiation, which excites a phosphor coating (in fluorescent lamps) or produces visible colored light directly (in neon lights). The result is bright, long-lasting illumination. That has served commercial needs for much of the 20th century.

Although LEDs have largely taken over efficiency and durability. Its lighting technologies remain relevant in niche applications, decorative signage, and specialized industrial lighting systems.

Plasma in Environmental and Industrial Applications

This technology is also commercially applied in environmental protection and industrial cleaning. Its torches, for example, are used in waste treatment facilities. To break down hazardous materials at extremely high temperatures. Its arc can decompose toxic compounds into simpler ones. It has fewer harmful elements, providing a cleaner method of waste disposal.

Plasma-based air purification systems are increasingly used in commercial buildings. In airplanes and public facilities. These systems generate plasma to produce reactive species. That neutralizes airborne pollutants, bacteria, and odors. The result is improved air quality without the use of chemical sprays or filters. That must be a frequent replacement.

Its role in environmental technologies demonstrates its growing importance in sustainability by enabling cleaner industrial practices and safer waste treatment. It contributes to both commercial success and ecological responsibility.

The Future of this Technology in Commercial Use

The commercial use of it is far from static. It is expanding into new and innovative applications. Research is underway to harness it. For water purification, renewable energy generation, and even space propulsion systems. In commercial agriculture, its treatment is being tested. To improve seed germination and reduce crop diseases.

Advances in its medicine hold promise for wound healing, in cancer treatment, and targeted drug delivery. At the same time, many of these applications are still in the early stages of development. Their potential to revolutionize industries. To ensure it remains at the forefront of technological innovation.

As commercial markets demand faster, cleaner, and more efficient solutions. It offers a versatile and scalable approach. Its ability to manipulate matter at both microscopic and macroscopic levels. It is uniquely suited for solving challenges across diverse fields.

FAQ’s

What is it, and why is it called the fourth state of matter?

It is a state of matter consisting of ionized gas particles—ions and free electrons. It conducts electricity and responds to electromagnetic fields. It is called the fourth state of matter because it differs from solids, liquids, and gases. It has unique properties that make it suitable for technological applications.

Which industries rely most heavily on this technology?

Industries such as electronics manufacturing, healthcare, automotive, aerospace, and environmental protection rely heavily on plasma. Its processes are essential for semiconductor fabrication, medical sterilization, surface treatments, and waste management. And also specialized lighting systems.

Why does it display as no longer popular?

Its displays were replaced by LED and OLED technologies. These newer displays are thinner, more energy-efficient, and have a longer lifespan. Its televisions were revolutionary in their time. And showcased the power of its in consumer electronics.

How does it differ from traditional sterilization methods?

Its sterilization uses reactive species generated in it. To kill microorganisms at low temperatures. Unlike steam or chemical sterilization, it can sterilize heat-sensitive equipment. Without leaving harmful residues, making it ideal for delicate medical devices.

What future applications of this technology are being developed?

Future applications include plasma-based water purification, agricultural treatments, renewable energy solutions, and advanced medical therapies. Research also explores its propulsion systems for spacecraft. Potentially enabling faster and more efficient space travel.

Conclusion

Plasma, often overlooked in daily life, plays a vital role in many commercial technologies. From its display panels that once dominated home entertainment. To semiconductor manufacturing that powers the digital age. From sterilization systems that safeguard medical practices. Its contributions are vast and indispensable.

Its applications extend into surface modification. Its lighting, environmental systems, and emerging medical treatments, showcasing its versatility. Plasma is not confined to scientific laboratories. But has entered mainstream markets, shaping industries and influencing daily living.

In answering which commercial technology uses plasmas. The list is extensive. The displays, semiconductors, sterilization systems, lighting, and beyond. What unites these diverse applications is the ability of its to deliver unique properties. The precision, cleanliness, energy efficiency, and adaptability of these qualities that no other state of matter can provide.

As research continues to unlock new possibilities. The plasma’s role in commercial technology will only expand. Reinforcing its position as a cornerstone of modern innovation.